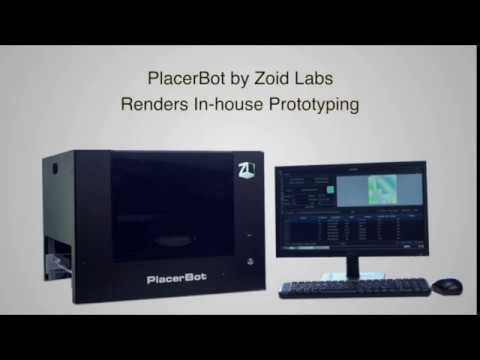

PlacerBot®

PlacerBot electronics assembly suite enables companies, R&D labs, and technical institutions to perform in-house electronics assembly to bring down development cost and cycle times. PlacerBot PCB assembly machines are engineered for start-ups and incubation centres. It is a desktop machine which accepts typical low volume feeds such as cut tape, comes with its own vacuum supply, has a friendly GUI that an engineer or technician can use easily. Yet providing accuracy and reliability on par with advanced commercial Pick and Place machines used in mass production.

Website : https://www.zoidlabs.com/

Current Status: Early revenues

Business Model: B2B

Product Description

Our product PlacerBot® suite is an innovative desktop solution for electronic assembly. It is India's first Desktop SMT assembly suite. It consists of a desktop sized pick and place robot, solder paste dispensing solution and reflow ovens

The PlacerBot suite is optimized for prototyping. It is a desktop machine which accepts typical low volume feeds such as cut tape, comes with its own vacuum supply, has a friendly GUI that an engineer or technician can use easily. Yet there is no compromise on accuracy; it is able to place tiny 0201 parts (0.6mm x 0.3mm) and fine pitch (0.5mm pitch) ICs on par with advanced commercial Pick and Place machines. Existing Pick and Place machines, being designed primarily for the EMS market, are not optimized for prototyping. They are heavy, occupy large space, require trained operators, require higher volume of component feeds (e.g. component reels rather than cut tape), compressed air etc.

PlacerBot also comes with our innovative low cost component feeders (Patent Pending) specifically designed for handling cut tapes. This significantly reduces the total cost of ownership as the cost of these feeders are negligible compared to other solutions in the market. The feeders can be quickly swapped and QR code based feeder identification ensures quick and easy set-up of the machine for assembly.

PlacerBot will empower the potential innovators by reducing the debug cycles and time and labour involved PCB assembly and inspection. The solution also eliminates the IP theft risk as the entire development process could be conducted in-house in a cost effective manner. It is self-contained desktop unit that eliminates the customised infrastructure required in the case of conventional pick and place machines